Alignments Equipment

I. Unger (96) Ltd. specializes in identifying misalignments and in performing top quality professional alignments, with a skilled, experienced team that provides solutions to customers 24/7.

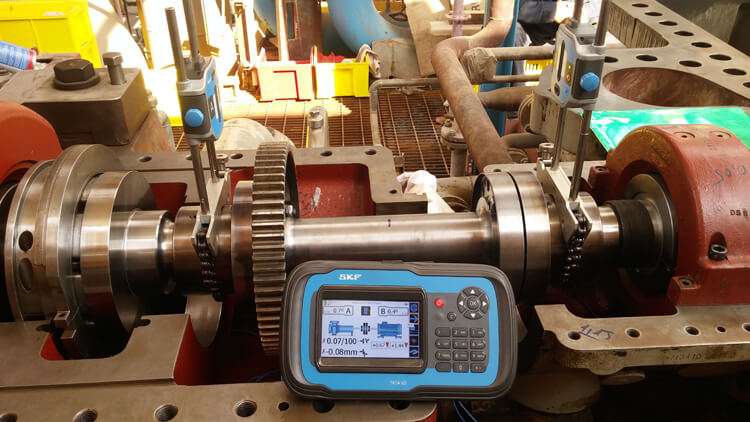

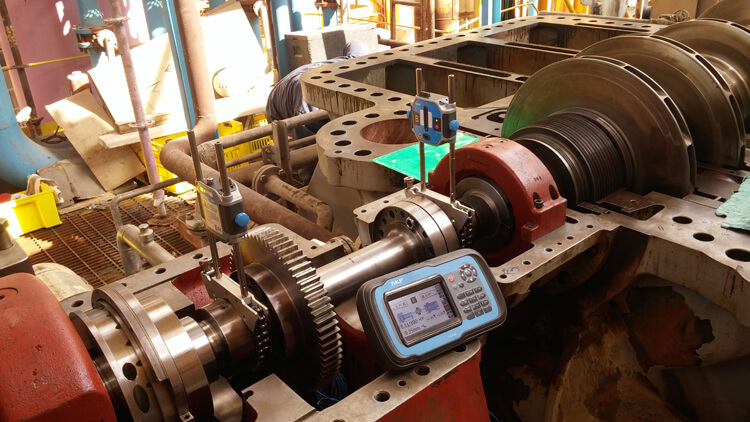

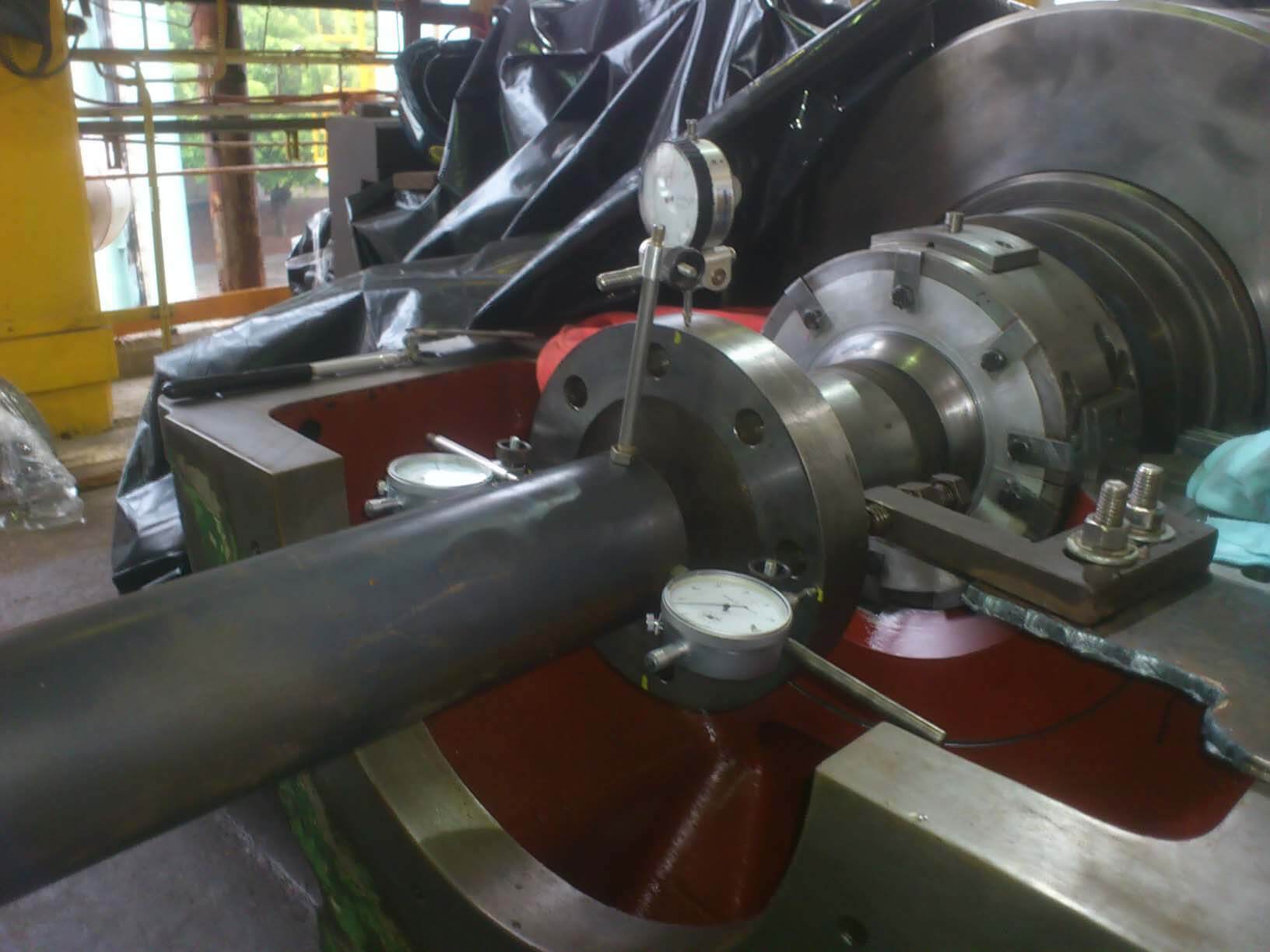

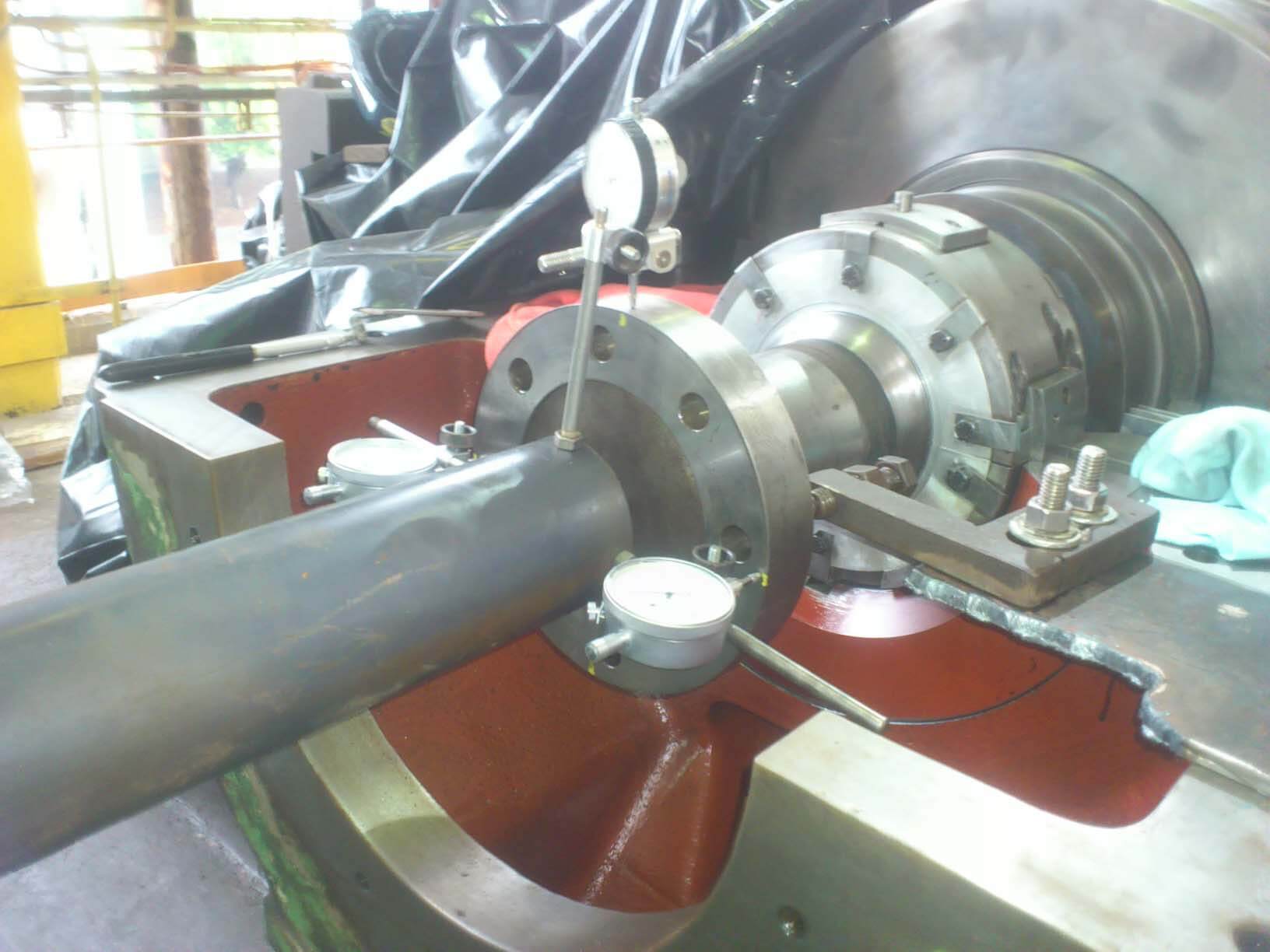

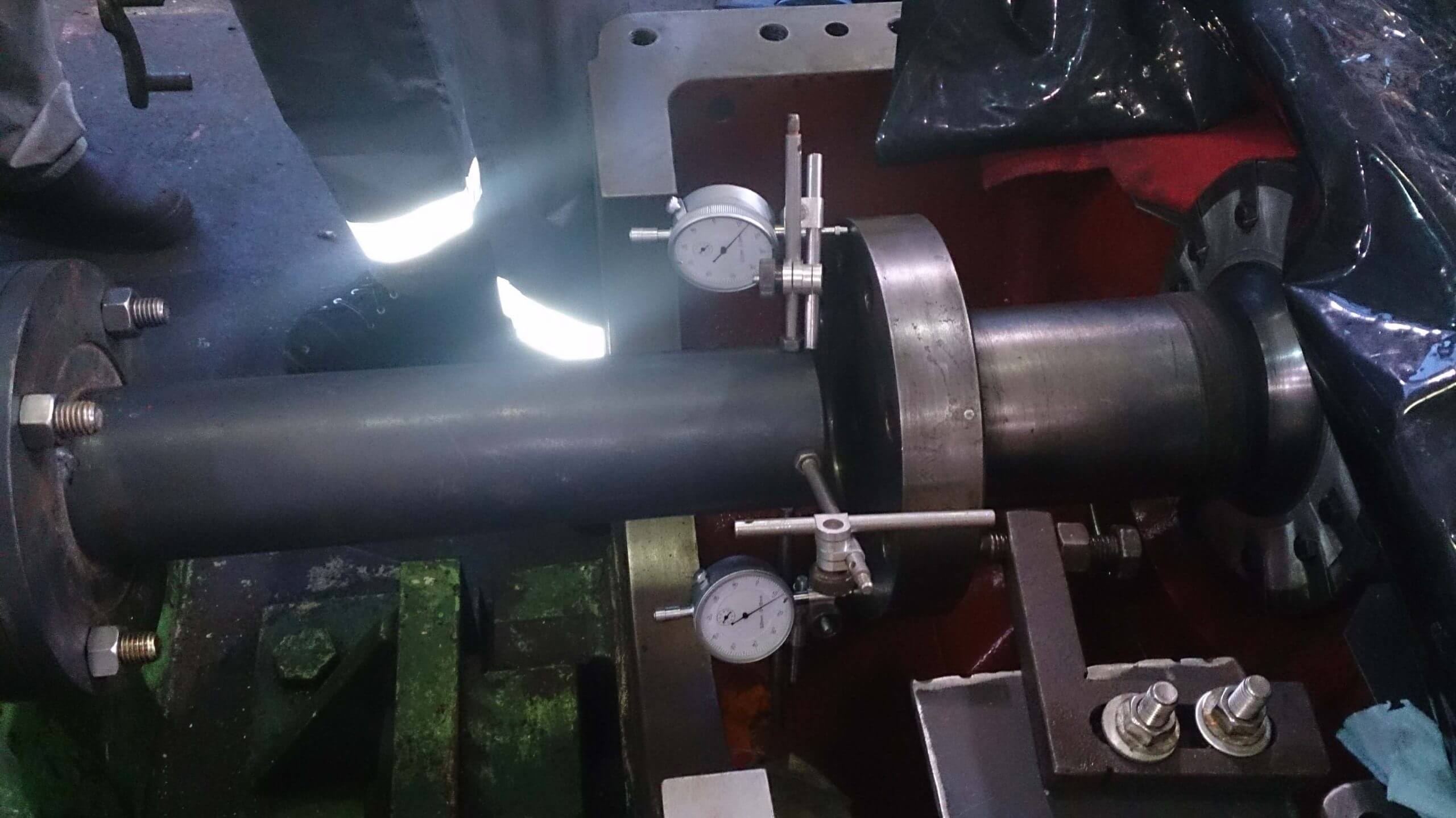

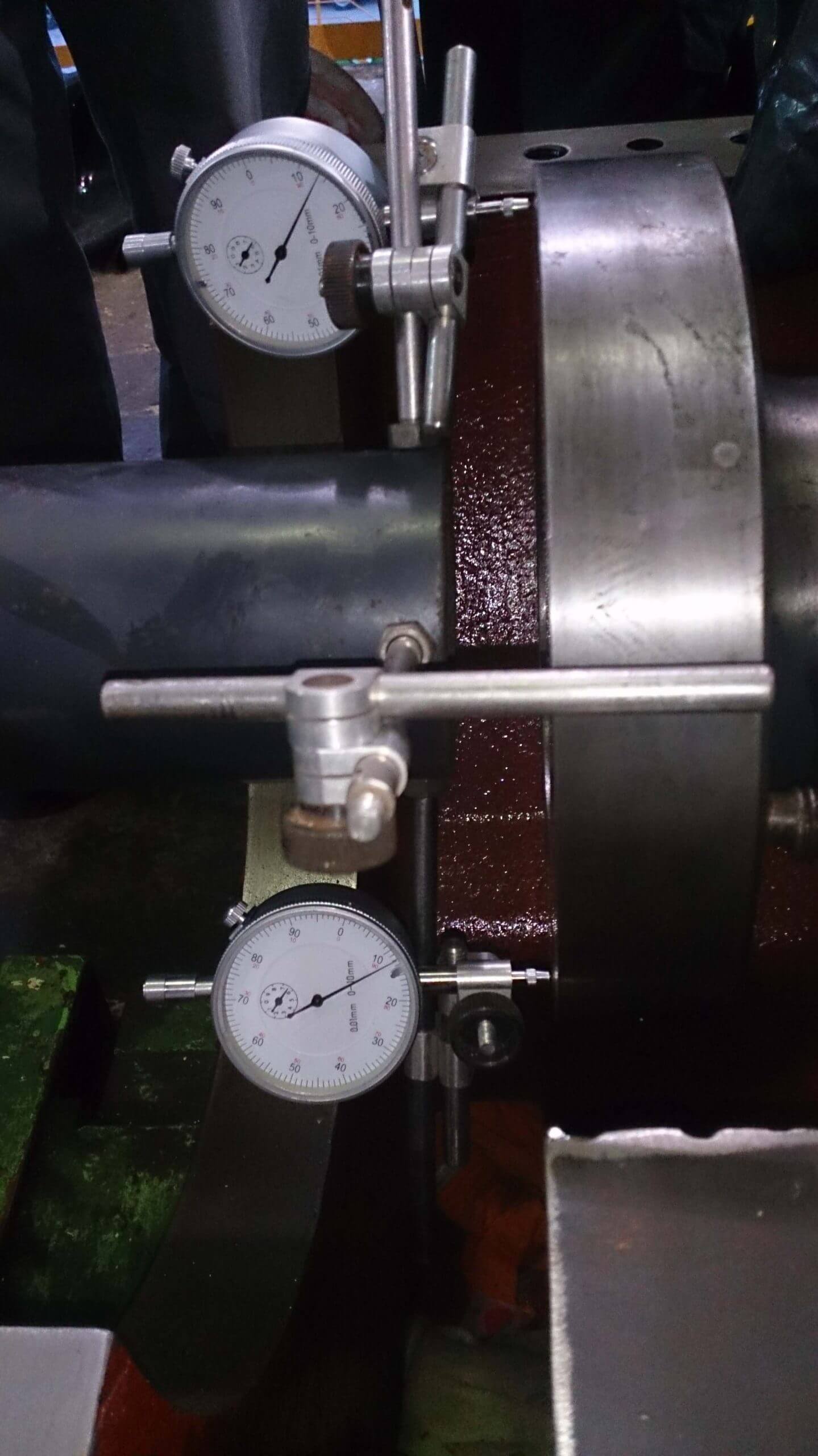

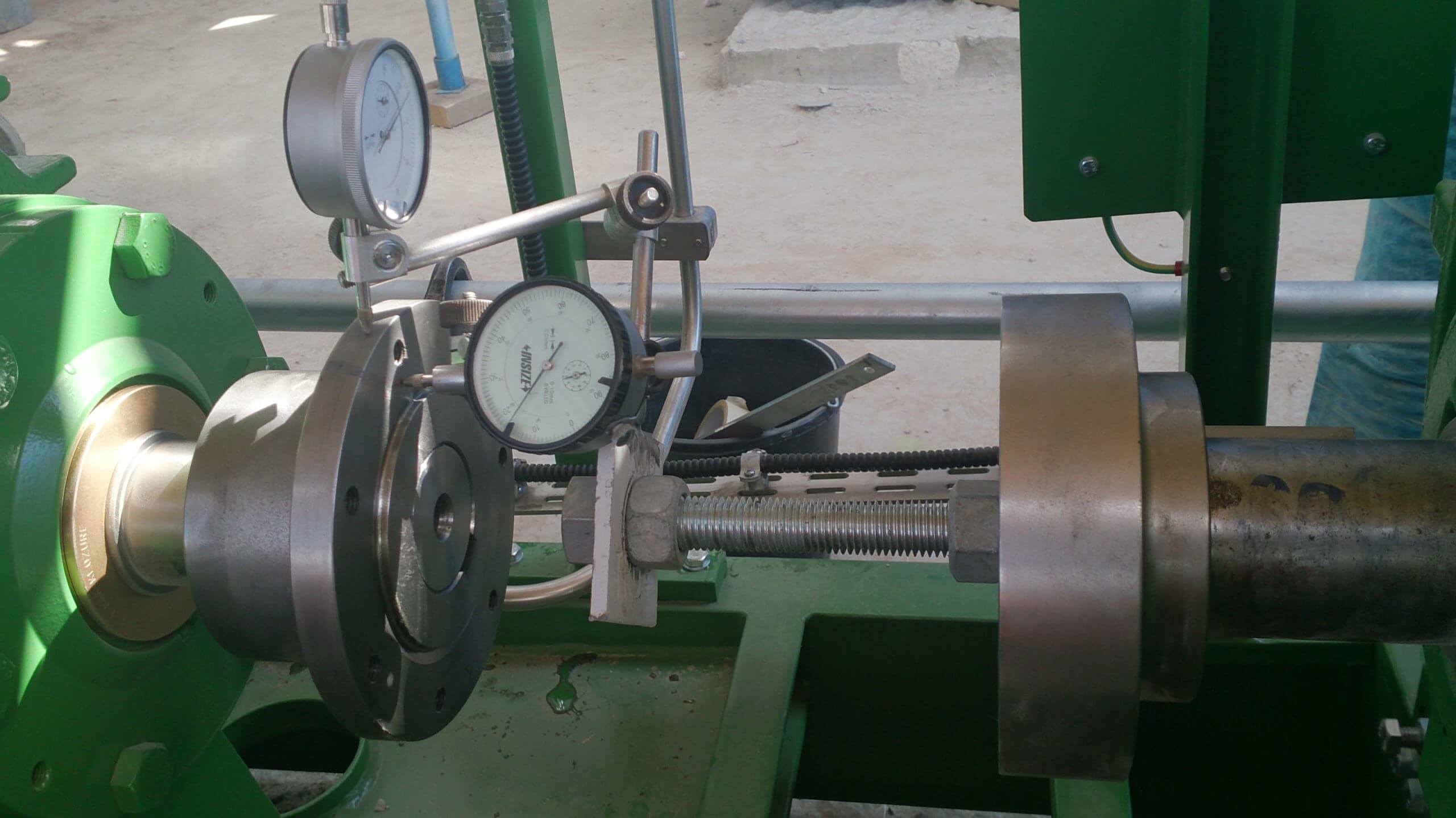

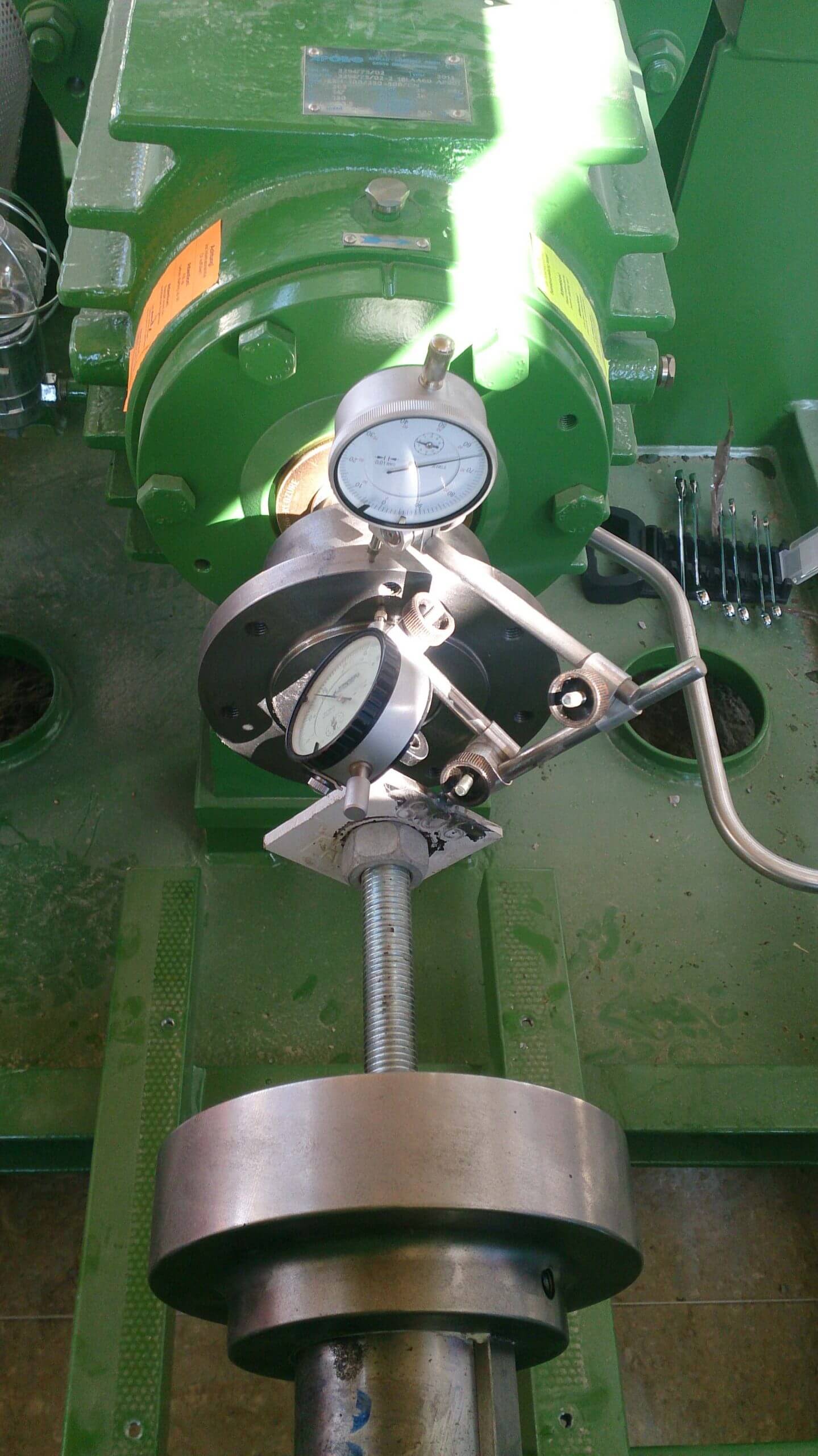

The Company performs alignments using indicators (clocks) and laser. The alignment procedure involves bringing two axes to maximum overlap of their symmetrical axis on all planes so that they essentially constitute one extension axis.

This procedure is designed to operate the equipment in an ultimate manner, causing the equipment to work without vibrations, in relative quiet and with maximum efficiency while protecting the bearings and life span of the equipment. Alignment is prerequisite for normal function of rotating equipment.

Misalignment might be attributed to a parallel and angular deviation between the machine’s axes, as well as a warped or loose machine bearing, one leg of an engine that is not parallel with the others or a different fastening between the engine legs. Misalignment might cause tremendous damage, including financial damage that might be attributed to damages caused by operating failures and increased wear and tear of the rotating equipment that results in high costs. Misalignment might also reduce the life span of the machine’s bearings and seals, and even cause vibrations in the rotating equipment.